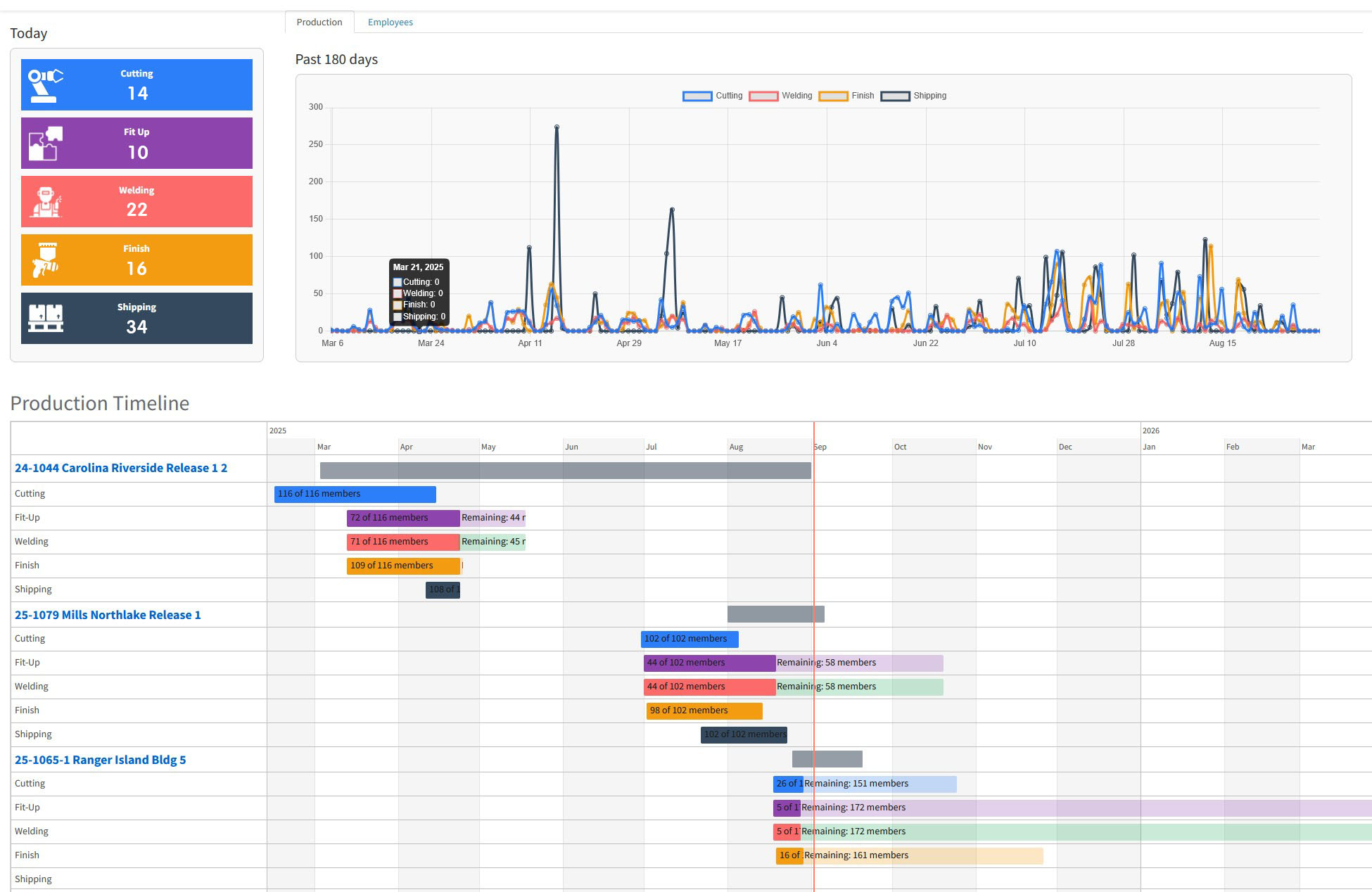

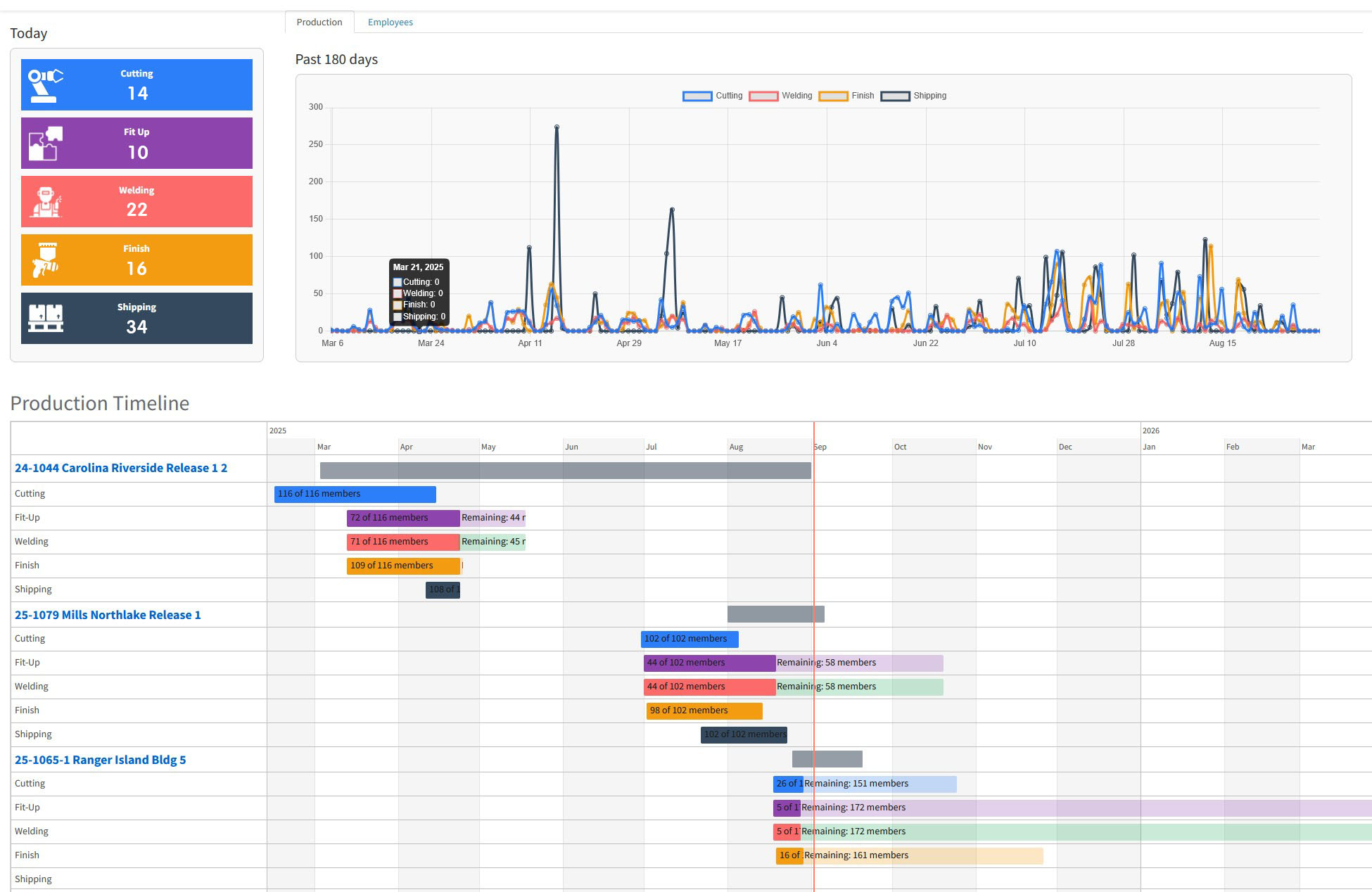

Your data at a glance

Your data is all in one place on a clear, intuitive dashboard. You will be able to see project progress, team assignments, and key metrics at a glance, quickly spot bottlenecks, and make informed decisions—keeping your operations efficient and on track..

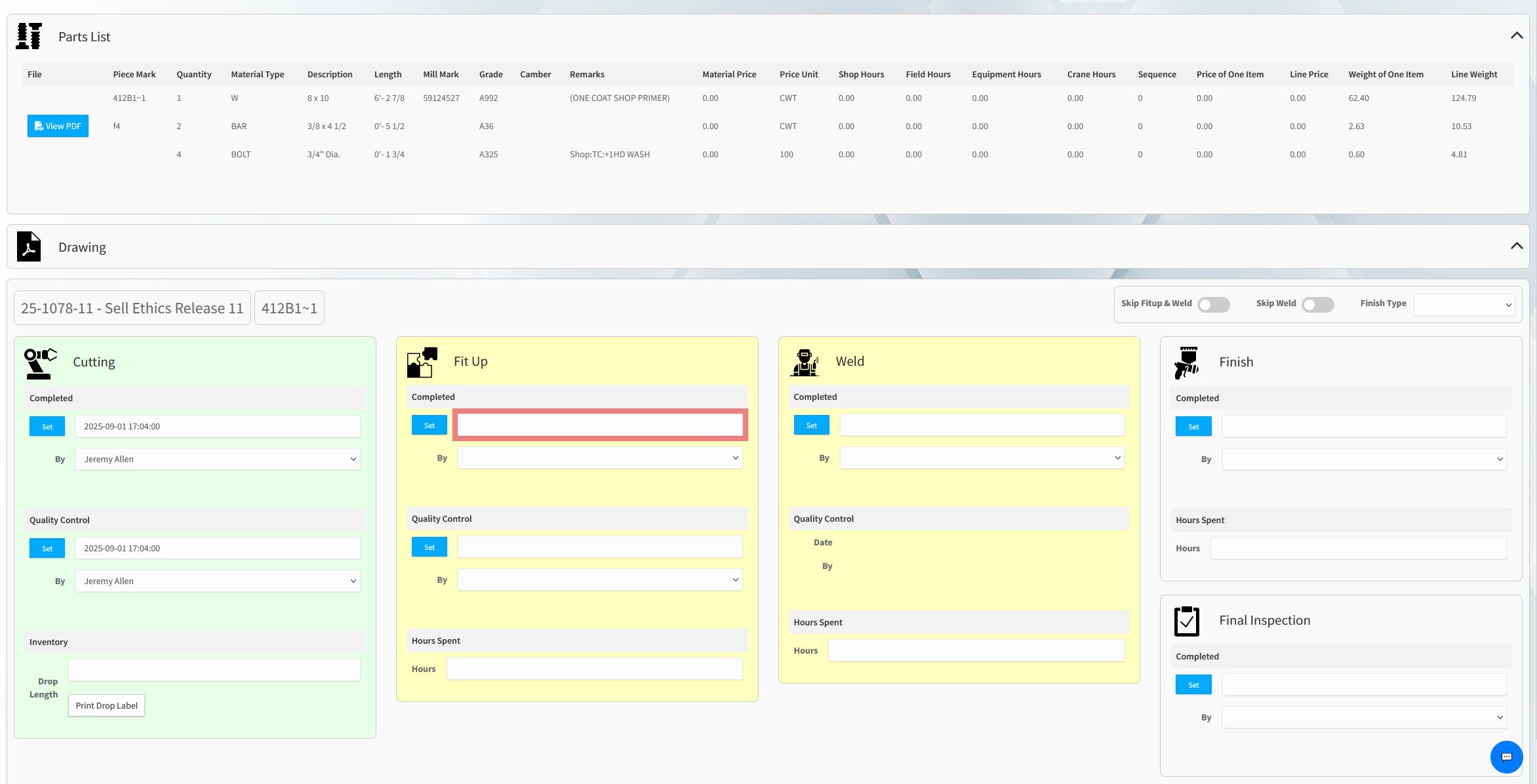

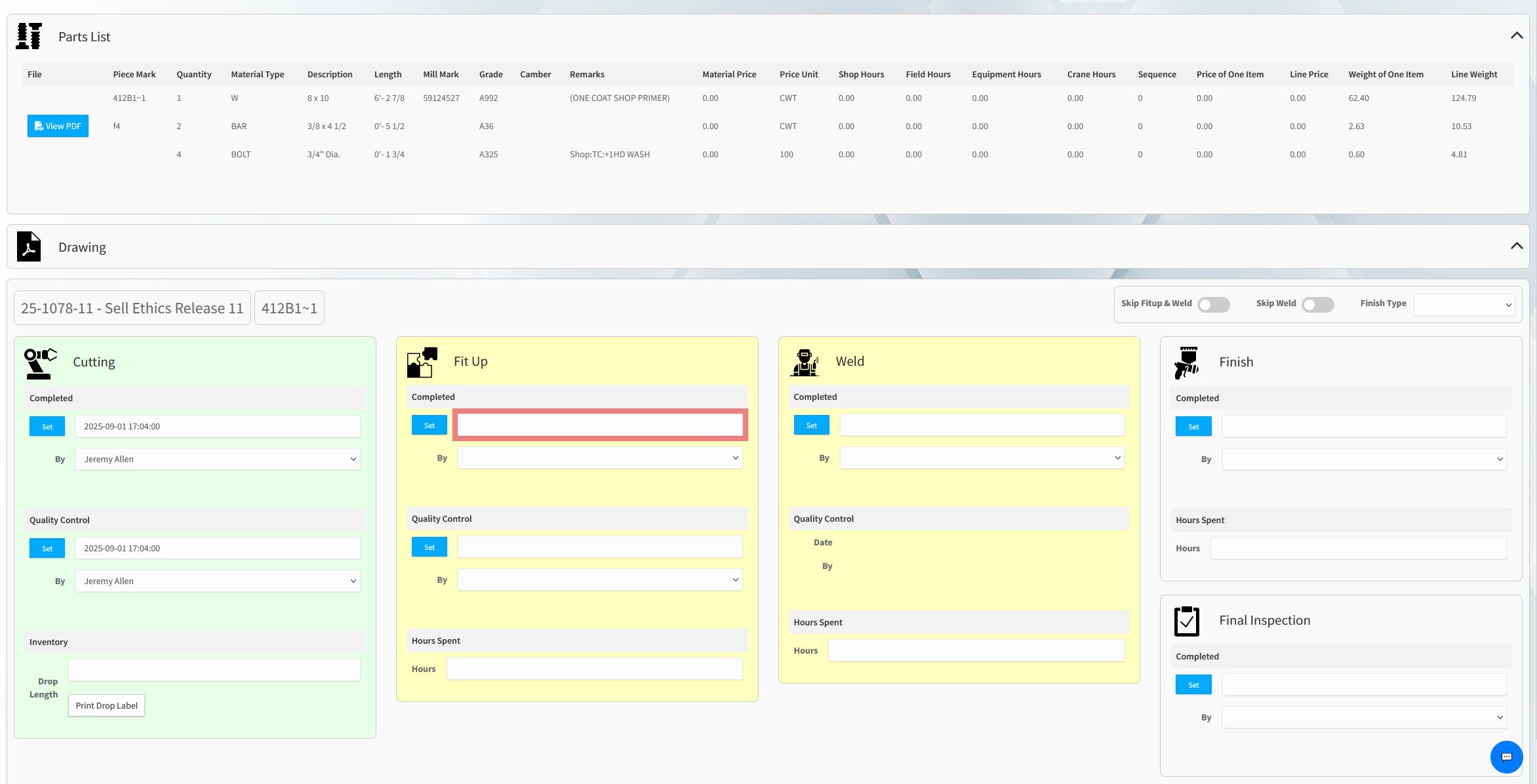

Simple member tracking

Workers will be able to update their progress effortlessly. By simply scanning a QR code with a tablet, they can mark a work stage as complete with a single click—automatically recording the time, date, and their name. This makes tracking work fast, accurate, and hassle-free.

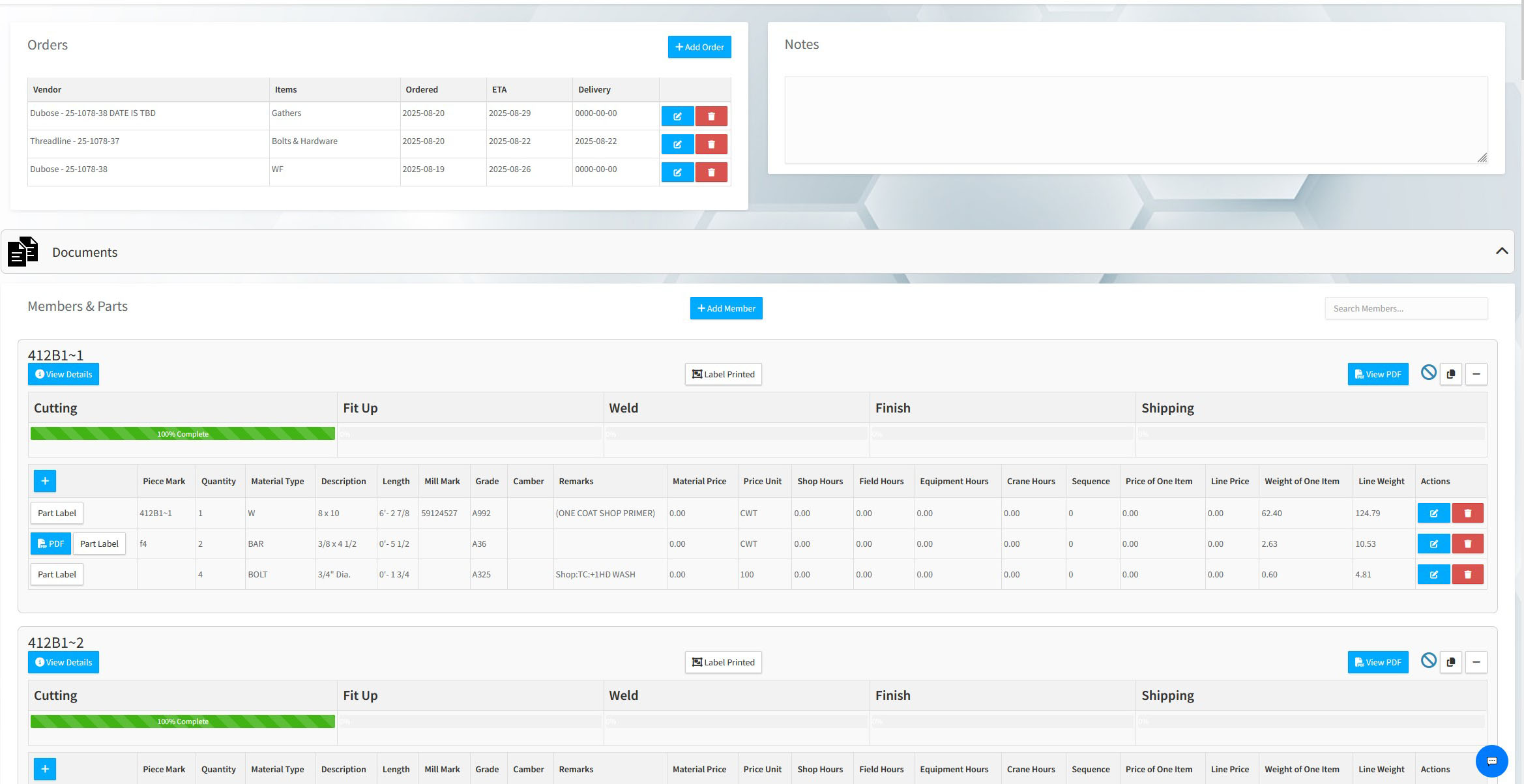

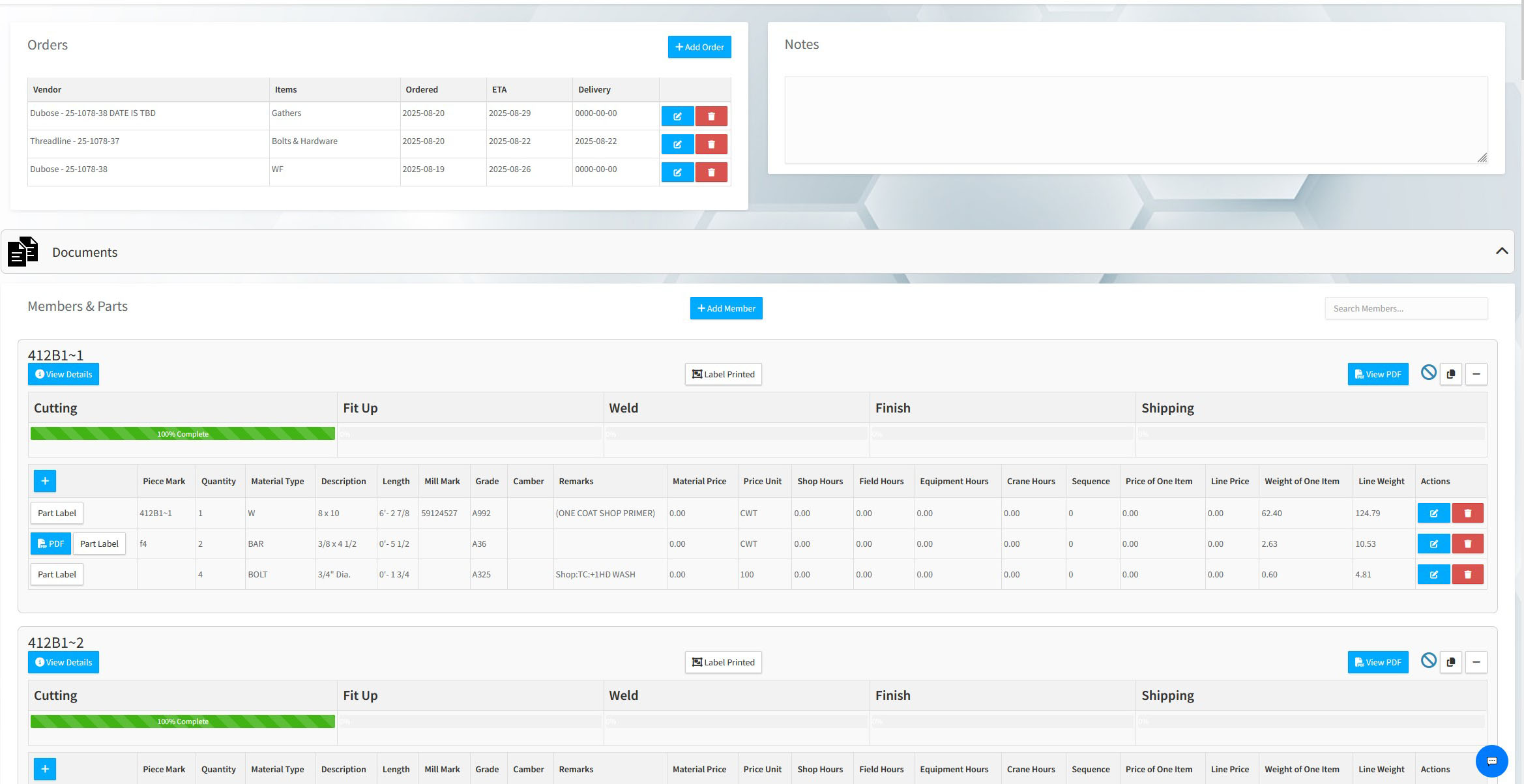

Easy access to project details

You will be able to see all project details in one place and easily manage every aspect of your work. You can upload and access drawings, track progress in real time, and edit parts or members directly—giving you full control and visibility over your projects.

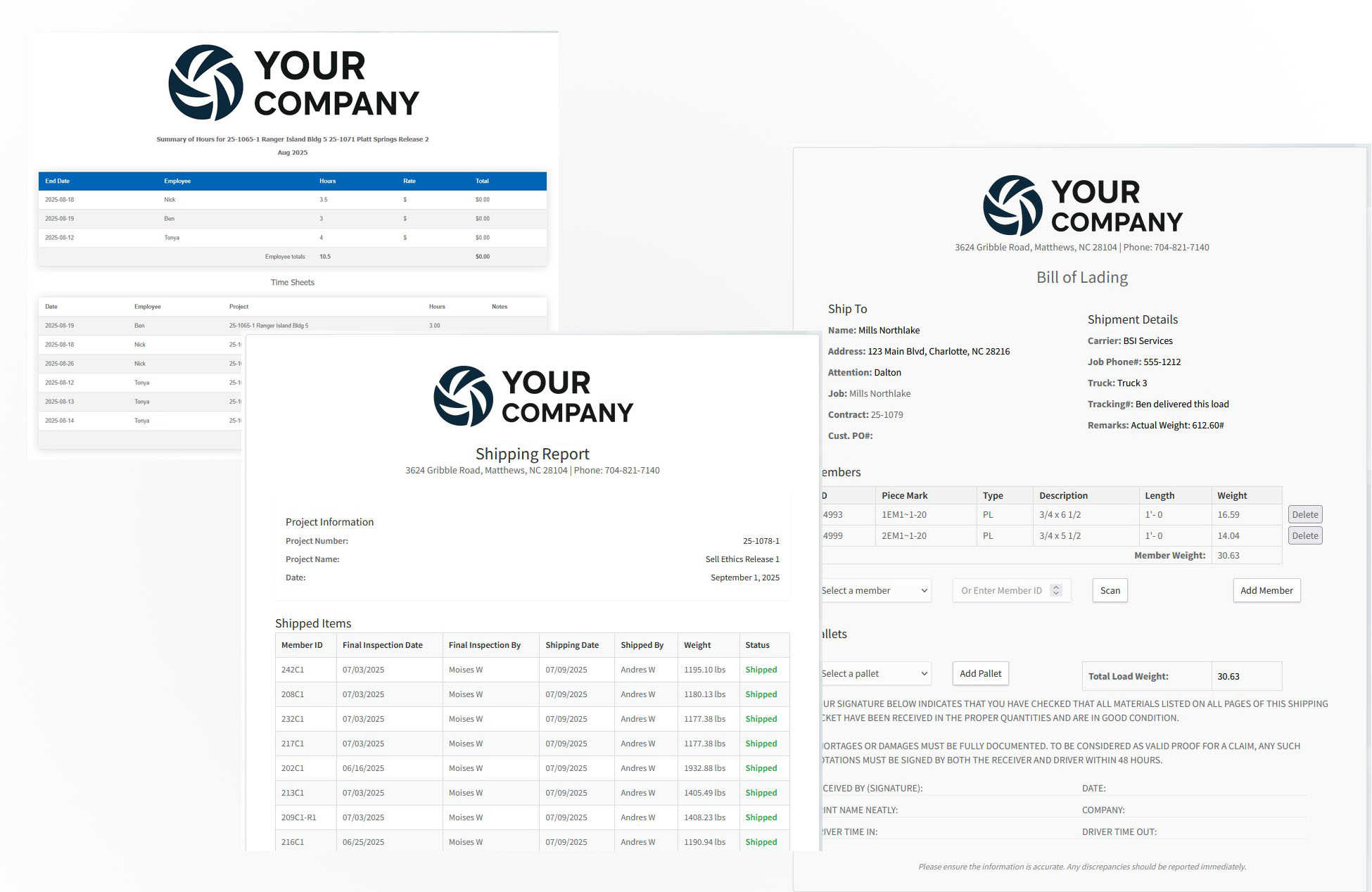

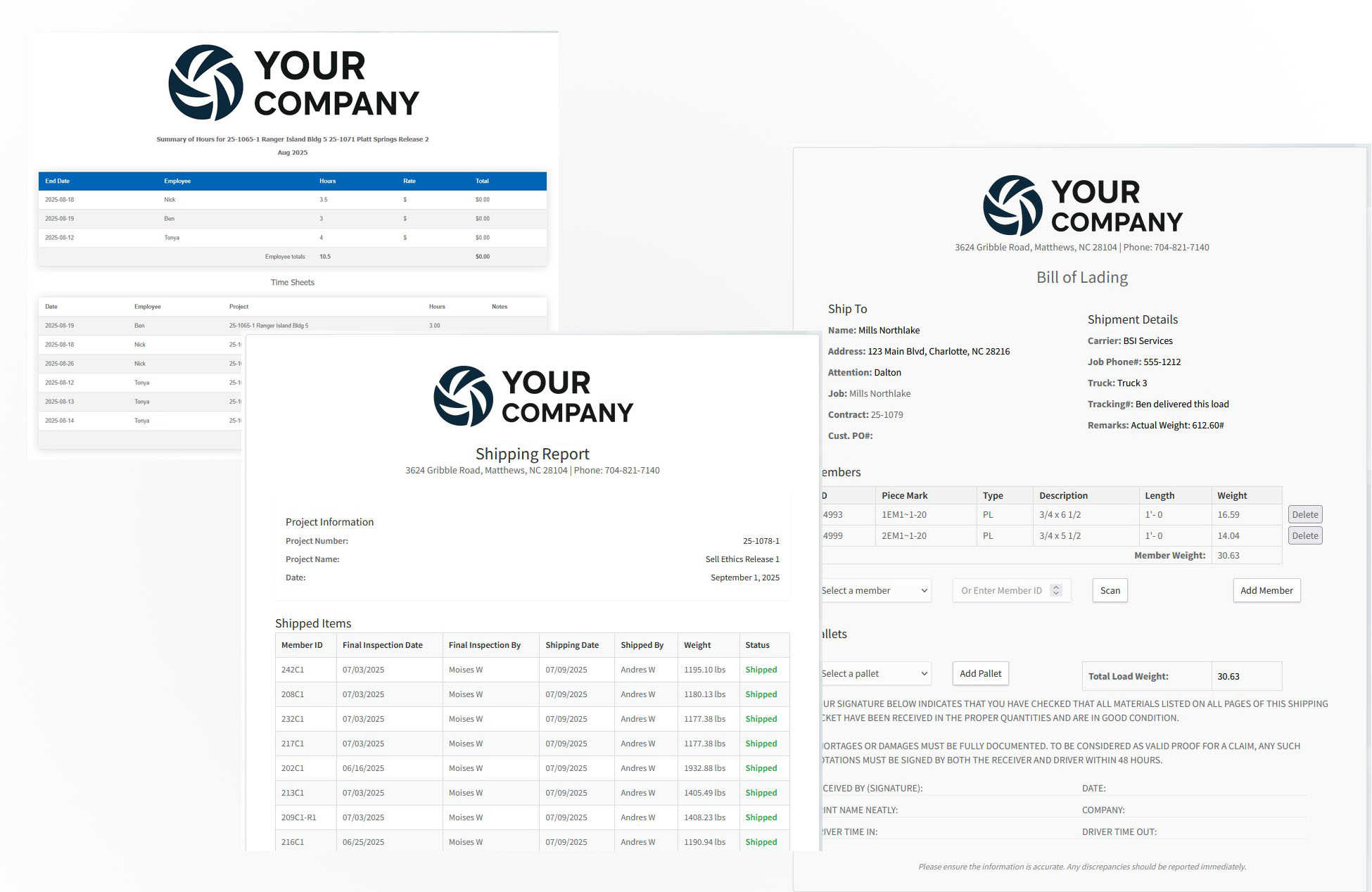

Export reports

Generate detailed reports quickly and accurately. From work reports and audit reports to employee summaries, everything is organized for easy access. Bills of lading can be built instantly by scanning a barcode to add members, streamlining shipping and documentation so you always have reliable records at your fingertips.